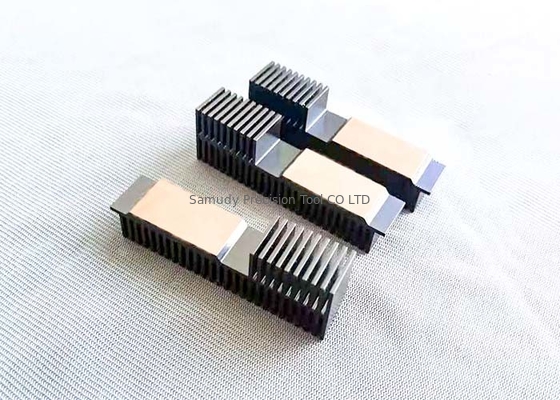

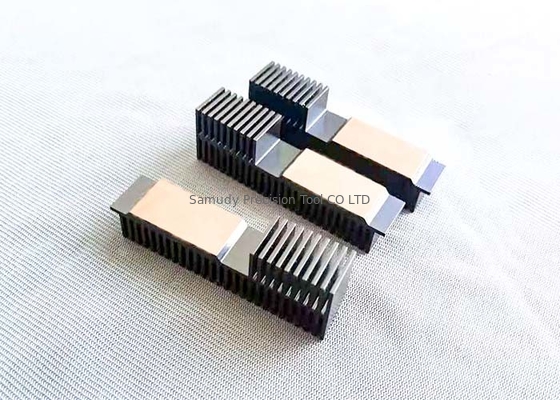

Copper CPU Heat Sink, die casting heat sink

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Heatsink Material | Copper & Aluminum | Type | Skiving Fin Heat Sink |

|---|---|---|---|

| Process | Extrusion, Skiving Fin, Stamping, Die Casting, Precision CNC Machining, Drilling, Milling, Bending, Soldering | Surface Finish | Anodizing, Electrophoresis, Nickel Plating, Sandblasting, Power Plating, Wire Drawing, Polishing, Anti-oxidation Coating, Etc. |

| Application | 1. Computer Fileds: Computer Mainboard, PC, IPC, Server, PCTV, Router, Power Supply (CPU Cooler, VGA Cooler, Cooling Fan) 2. Home Appliances: Pico Projector, Electronic Refrigerator, Red Wine Cooler, LASER TV, LCD TV, LED Panel, Sound, Air Condition, Indu | Delivery | 25-30 Days After Confirming All Inforamtions |

| High Light | aluminum machining part,precision aluminum parts |

||

Copper CPU Heat Sink, die casting heat sink

Product Description:

| Product type | Heat sink of Foreced Air cooling,natural air cooling , water cooling, Heat pipe, LED, electriacal vehicle, etc series. |

| Material | Pure copper, Stainless Steel |

| Sizes | Have more than 1000 existing modes, also can be customized design. |

| Production Process | Profile extrusion, Cutting,Deburring, CNC Processing, Stamping,(drilling holes, tapping,Chamfering,Milling),(Brushing, Sandblasting, soda boiling,polish)Surface Treatment(Anodization, Painting, E-coating, Nickel plating), 100%Inspection(Function,Cosmatic), Assembly,Package, etc. |

| Surface oxidation | Black anodizing, Clear anodization,Painting,E-coating, Nickel plating,etc. By your request. |

| Application | Computer.Data Server.New energy vehicle ,SVG/SVC/ APF/ frequency converter, inverter, charging device. Welding machine. Welding controller/ power supply(induction heating/ rectifier/ inverter power/ electroplate power/ SMPS/ military / laser power supply/ ) power regulator/ soft start/ broadcast communication( base station/ signal shielding brodadcast transmitter, power amplifier ) electronics,extruded heat sink, heat pipe heat sink, stamping heat sink,die casting heat sink, precision CNC machining heat sink, heat pipe, cooling fan: DC computer case fan, AC fan, EC fan, Thermo Electric Cooler. etc. |

| Devices | extrusion lines,Cutting machines, CNC machines, Stamping machines,milling machines, drilling machines,polish machine,laser machines,anodization line,assembly lines. etc. |

| MOQ | There is no MOQ requirements if we keep stock for existing models, MOQ can be negotiated. |

| Packing | Foam, Carton, Wooden case, which is suitable for. |

| Payment Term | T/T, L/C |

| Lead Time | Normally 15-20 working days after deposit received. |

| Shipping Port | Shenzhen, China |

| Delivery | By Sea, By Air |

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 10-15 days . or it is 15-20 days if the

quantity is larger

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of

express shipping fee

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in

advance ,balance before shippment.

Company Service

Our service includes the plastic mould, magnesium / zinc alloy die casting, aluminum alloy forging parts, as well as mobile phone and digital products, mold design, manufacturing, R & D, production, other secondary processes.

About Us

Samudy Precision Tool Co Ltd was founded in 2006. Through 13 years of development and investment, Our company has become a leading “one-stop manufacturing service” provider in China, certified to ISO9001:2008, AWARDED AS “High-Tech Enterprise of China”.

Our factory is located in the beautiful southern China s Pearl River Delta on the west coast of Shenzhen, with a manufacturing space of 5,000㎡ and a workforce of over 260 employees. Our factory structured with independent teams of Quality, Project Management, Design, Engineering, and Manufacturig.