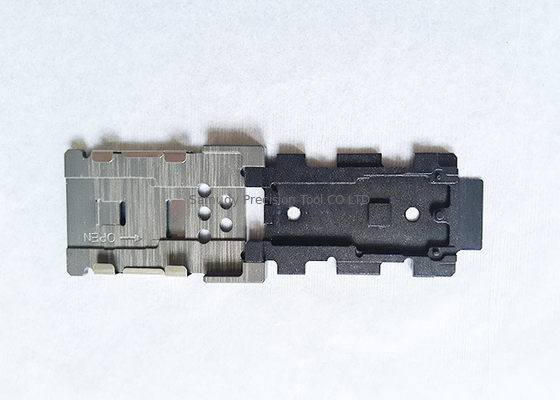

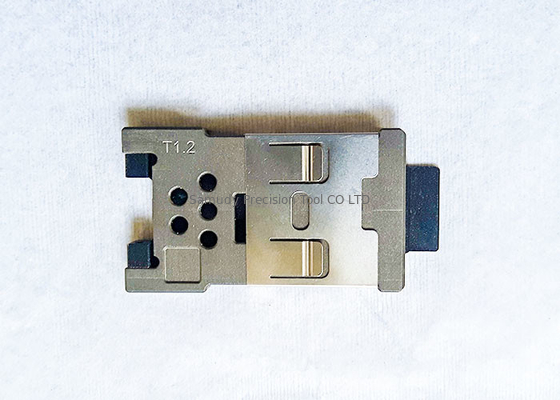

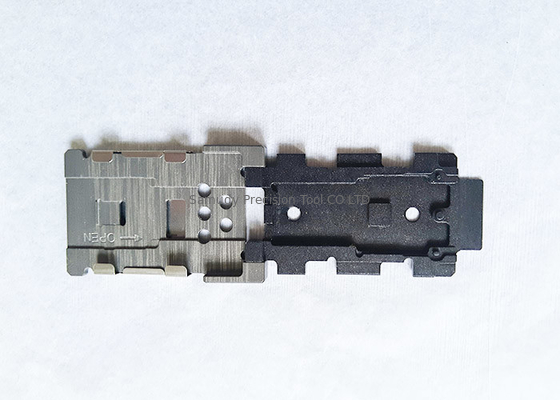

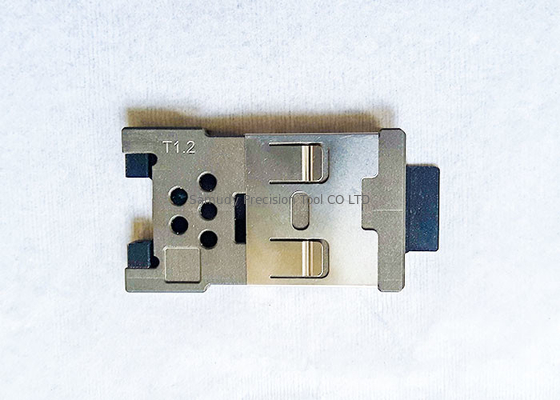

Hard Anodized Aluminum Parts CNC Machined High Precision Wear Resistant

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| AL6061-T6 | CNC Cutting +Hard Anodized | Material | Aluminum Alloy,Brass,Stainless Steel,Carbon Steel |

|---|---|---|---|

| Finish | Powdering,rust Preventive Oil, Titanium Alloy Galvanized | Management System | ISO9001:2008 |

| Highlight | anodized car parts,cnc precision machining parts |

||

CNC Machined Aluminum Anodized Parts

product description:

| Material | Aluminum alloy,Brass,Stainless Steel,Carbon steel,according to customer's requirement |

| Finish | Milled /Tin plating, copper-plating,hot-dip galvanizing, black oxide coating,red anodized,black anodized,painting, Powdering,rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Testing Equipment | CMM,Projector,Pull Tester,Automatic Optic Inspector,Projecting apparatus Salt Spray Test, Durometer, and Coating Analyzer,Tensile Machine |

| Management System | ISO9001:2008 |

| Certification | SGS,RoHS,Material Certication,PPAP |

Production Capability |

Auto-lathe turning:OD0.5-20mm,Tol.0.01mm |

| CNC lathe turning:OD0.5-250mm,Tol.0.005mm | |

| CNC Milling:800x600mm(LxW),Tol.0.05mm | |

| Grinding:Tol.0.002mm | |

| Screw heading &rolling:Metric 0.8-M6,Unified Imperial#0-1/4'' | |

| Stamping:200T max | |

| Lead Time | 5-15 working days |

| Samples | Welcome |

| Delivery term | By DHL,UPS,TNT,FedEx,EMS,By Ocean,By Air |

| Warranty | Replacement at all our cost for rejected products |

Our service:

Samudy Precision Tool Co Ltd bring in 800 T Cold Chamber Die asting Machine, Hou Er 25 T Punch Machine, CNC1050, CNC850, CNC840, Tokugawa four-axis device, Mirror EDM Machines to ensure superior quality. Our factory is located in the beautiful southern China s Pearl River Delta on the west coast of Shenzhen, with a manufacturing space of 5,000㎡ and a workforce of over 260 employees

Our service includes the plastic mould, magnesium / zinc alloy die casting, aluminum alloy forging parts, as well as mobile phone and digital products, mold design, manufacturing, R & D, production, other secondary processes.

Our Advantages:

A. Full range equipment, all the normal prototyping can be finished.

B. Short lead time: 3 days.Good quality, fast delivery, low cost.

Work with us, and you would see the difference!